Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

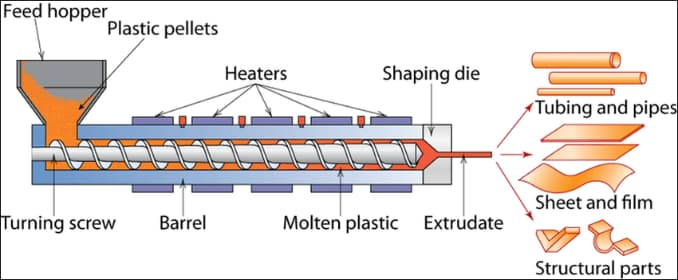

Plastic Extrusion Process

Introduction:

Plastic extrusion is a process used to shape plastic materials into various forms by forcing them through an extruder. The extruder consists of a hopper where the plastic material is fed, and a screw that rotates and pushes the material towards the head of the machine. During this process, the plastic material experiences high pressure due to the resistance of filters, deflectors, and the head mold, as well as the decreasing volume between the screw threads. Additionally, the plastic is heated by the heat source in the extruder barrel. As the plastic moves, it undergoes compression, shearing, mixing, and friction between the barrel and screw, as well as among the plastic molecules, generating a significant amount of heat. As a result, the temperature of the plastic in the barrel continues to rise, causing its physical state to transition from a glassy state to a highly elastic state and eventually reaching a molten, viscous state, achieving complete plasticization. The molten material is then extruded through the nozzle of the head mold in a pressure-controlled and volumetrically controlled manner, resulting in a plastic product with a specific shape. After cooling and shaping, the extrusion process is complete. The core component responsible for this process is the screw, and the extrusion process on the screw can be divided into several stages.

Stage 1: Feeding

After the plastic is added to the hopper, it enters the space of the screw groove by relying on its own weight or the action of the forced feeder, and is extruded forward under the push of the screw edge. However, if the friction coefficient between the material and the metal hopper is too large, or the internal friction coefficient between the materials is too high, or the cone angle of the hopper is too small, bridges and hollow tubes will gradually form in the hopper, and the material will not flow smoothly. If it enters the screw channel, the extrusion will be forced to stop or become extremely unstable. Therefore, if the extrusion productivity decreases abnormally or no material is discharged, the feeding situation must be checked or even the design of the hopper must be changed.

Stage 2: Conveying

Theoretically, after the plastic enters the screw groove, every time the screw rotates, all the plastic will be transported forward by one lead. At this time, we call the transport rate 1. But for each screw, the forward conveying volume actually mainly depends on the friction factor fb of the plastic to the barrel and the friction factor fs of the plastic to the screw. The larger fb or the smaller fs, the amount of solid plastic transported forward will be The more. A large number of experiments show that the friction factor of resin against metal mainly depends on the temperature of the system and the surface roughness of the metal or the structure and shape of the system. It is also related to the system pressure and material movement speed.

Stage 3: Compression

It is absolutely essential that the plastic is compressed during the extrusion process. First of all, plastic is a poor conductor of heat. If there are gaps between the particles, it will directly affect its heat transfer and thus the melting rate. Secondly, only under gradually increasing pressure along the length of the screw will the gaps between the particles be The gas is discharged from the hopper, otherwise, the product will become a defective or waste product due to bubbles generated inside it; finally, the higher system pressure also ensures that the product is relatively dense.

There are three reasons for the pressure on the screw:

1. In terms of structure, the depth of the screw groove gradually becomes shallower, and the material is gradually compressed;

2. Resistance components such as a diverter plate, filter screen, and machine head are installed in front of the screw head;

3. It is the pressure established along the entire length of the screw caused by the friction of the material against the metal. The smaller the die cross-sectional area of the die, the greater the pressure peak will be, and the highest pressure point will move toward the die. Generally speaking, the pressure peak is at the front of the metering section or the rear of the compression section.

Stage 4: Melting

While the pressure rises, the moving solid plastic is in constant contact and friction with the heated barrel wall. The temperature of the plastic material close to the barrel wall continues to increase. After reaching the melting point, a thin layer of plastic material is formed on the inner wall of the barrel. Melt film, after this, there are two sources of heat for solid plastic melting. One is the conductive heat from the external heater of the barrel, and the other is the shear (internal friction) caused by the different movement speeds of the melt in each layer in the melt film. ) heat, which is the viscous dissipation heat referred to in rheology.

As the melting progresses, when the thickness of the molten film is greater than the gap between the screw and the barrel, the moving spiral edge scrapes off the molten film, forming a molten pool in front of the advancement of the spiral edge. During the melting process, the molten pool becomes wider and wider, and the remaining solid width becomes narrower and narrower, until it finally disappears completely. This is the famous and epoch-making melting theory published by Tadmor in 1967.

Stage 5: Mixing

During the extrusion process, under the action of high pressure, solid materials are generally compacted into dense solid plugs. Since there is no relative movement between the particles in the solid plugs, the mixing effect can only occur between the melt layers with relative movement. conduct.

Generally speaking, the following mixing phenomena occur in the melt, especially in the melt conveying section: First, the components in the material system are uniformly dispersed and mixed. These components refer to resin and various additives. The second is the mixing of heat. This is because during the extrusion process, the material that melts first has the highest temperature, and the material that melts later has the lowest temperature, and the temperature of the interface between the solid and the melt is exactly the melting point of the plastic. If the molten material is extruded from the machine head too early, it will inevitably cause unevenness in all parts of the extrudate, ranging from color difference and deformation to the possibility of product cracking. In addition, considering that the plastic itself has a certain relative molecular mass distribution, mixing can make the parts with higher relative molecular mass evenly dispersed in the melt. At the same time, under the action of shear force, the relative molecular mass The higher parts may be reduced by chain scission, which reduces the possibility of crystal spots and hard lumps appearing in the product. Obviously, in order to ensure a uniformly mixed product, the melt conveying section (i.e., the last section) of the screw must be of sufficient length. Therefore, the melt conveying section of the screw is also called the homogenizing section. At the same time, when calculating the output of the extruder, the volume of the groove in the last equal-depth section of the screw is used as the basis for calculation. The melt conveying section of the screw is also called the metering section.

Stage 6: Venting

During the extrusion process, there are three types of gases that need to be vented. The first type is air trapped between the resin particles. Generally, this gas can be expelled from the hopper as the pressure gradually increases, as long as the screw speed is not too high. However, when the speed is too high, the material moves forward too quickly, and the gas may not have enough time to escape, resulting in bubbles in the finished product.

The second type of gas is moisture absorbed by the material from the air, which turns into water vapor when heated. For plastics with low moisture absorption like PVC, PS, PE, PP, there are usually no issues, and this small amount of water vapor can be expelled from the hopper. However, for some engineering plastics like PA, PSF, ABS, PC, they have high moisture absorption, and there is too much water vapor to be expelled from the hopper, resulting in bubbles in the product.

The third type of gas is generated by certain materials within the plastic particles, such as low molecular weight volatiles and low melting point plasticizers. Under the heat generated during the extrusion process, they gradually vaporize. These gases can only escape when the plastic is melted and can overcome the surface tension of the melt. However, at this point, they have moved away from the hopper and cannot be vented through it. In such cases, a vented extruder machine must be used.

Therefore, every screw must fulfill the six basic functions: feeding, conveying, compressing, melting, mixing, and venting. Feeding and conveying affect the output of the extruder, while compressing, melting, mixing, and venting directly impact the quality of the extruded product. Here, quality refers not only to the complete melting of the material but also to the density of the product, uniform mixing, and the absence of bubbles. This is referred to as plasticization quality.

https://www.toponew.com/blog/understanding-the-basic-principles-of-plastic-injection-molding

https://www.toponew.com/products/pa6-compound/engineered-plastics-corporation-polyamide-6-6-nylon