Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

PPA Materials: Characteristics, Applications and Development

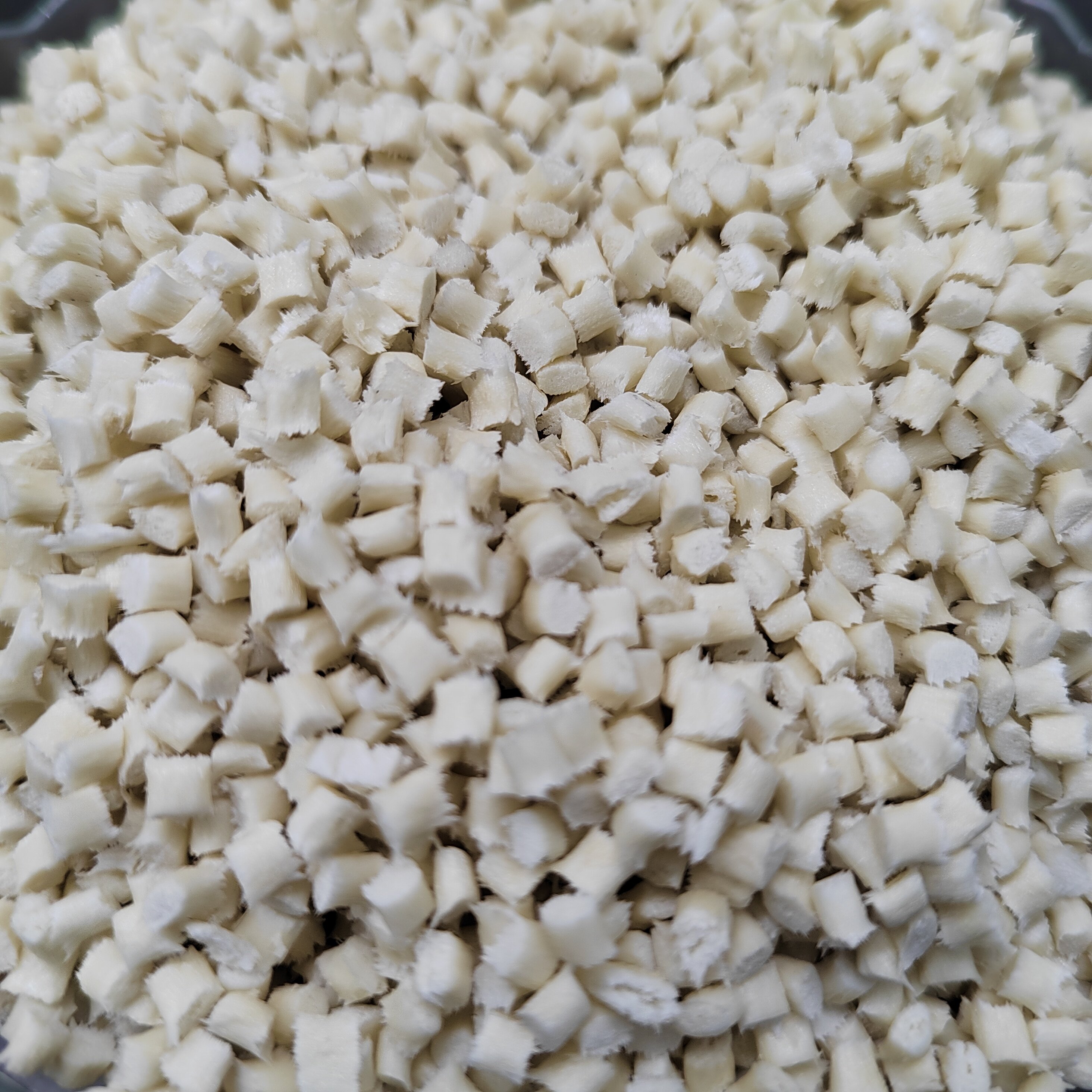

TOPONEW is a leading modified plastic granules manufacturer specializing in PPA granules. Our white label PPA granules offer a premium solution for various applications, supported by a robust PPA granules Supply Chain to ensure quality and efficiency. By outsourcing PPA pellets production to us, you can benefit from our expertise and industry-leading capabilities.

With the continuous advancement of science and technology, innovative materials like PPA are constantly shaping various industries. PPA, a high-performance polymer material, has gained recognition for its exceptional properties and wide-ranging applications. In this article, we will delve into the detailed characteristics, diverse applications, and promising development prospects of PPA materials. Trust TOPONEW for your PPA granules needs and discover the possibilities of this versatile material in your projects.

PPA GF30 PPA GF35 PPA GF45 PPA GF50

PPA material, polyamide-imide, is a high-performance polymer material with excellent mechanical properties, high temperature stability, electrical properties and chemical stability. Specifically, the advantages of PPA materials include:

1. Excellent mechanical properties: PPA material has high strength, high rigidity and high toughness, can withstand large pressure and friction, and can still maintain good mechanical properties in low temperature environments.

2. Good high temperature stability: PPA material has high thermal stability and can maintain its performance at high temperatures for a long time, making it suitable for applications in high temperature environments.

3. Excellent electrical properties: PPA materials have excellent insulation and dielectric properties and can be used to manufacture insulating materials and electronic components.

4. Good chemical stability: PPA material has good chemical corrosion resistance and can withstand the erosion of a variety of chemical substances, making it suitable for applications in the chemical industry.

Because PPA materials have excellent properties, they are widely used in various fields. Here are some common application areas:

1. Automotive industry: PPA materials can be used to manufacture automobile engine parts, transmission system parts and electrical system parts, etc., with excellent mechanical properties and high temperature resistance.

2. Aerospace field: PPA materials can be used to manufacture aircraft parts and spacecraft components, etc., and have the characteristics of high strength, high rigidity and high temperature stability.

3. Electronic and electrical fields: PPA materials can be used to manufacture electronic components, insulation materials, wires and cables, etc., with excellent electrical properties and chemical corrosion resistance.

4. Chemical industry: PPA materials can be used to manufacture chemical equipment such as corrosion-resistant pipes, valves, reactors, etc., and have good chemical corrosion resistance.

5. Other fields: In addition to the above fields, PPA materials can also be used in medical devices, sports equipment, precision machinery and other fields.

Development Prospects of PPA MaterialsWith the continuous development of science and technology, the application prospects of PPA materials are becoming more and more extensive. In the future, the development of PPA materials will mainly focus on the following aspects:

1. Development of new varieties: As people continue to conduct in-depth research on PPA materials, more types of PPA materials will be available in the future to meet the needs of different fields.

2. Improvement of processing technology: In order to better utilize the performance of PPA materials, it is necessary to continuously improve processing technology and improve material preparation efficiency and product quality.

3. Research and development of composite materials: Composite PPA materials with other materials can achieve better performance and wider application fields. In the future, composite PPA materials will become an important direction of research.

4. Environmental protection and sustainable development: With the continuous improvement of environmental awareness, the production and use of PPA materials need to pay more attention to environmental protection and sustainable development to reduce the impact on the environment.

5. Intelligence and digitalization: With the continuous development of intelligent and digital technology, future PPA materials will be more intelligent and digital, and can better adapt to the needs of intelligent manufacturing and digital transformation.