Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

The Power of Reinforcement: Uncovering the Benefits and Drawbacks of Modified Plastic Granules

Introduction:

Plastic materials experience significant improvement in their physical and mechanical properties when reinforced with glass fibers. Common plastics like Polypropylene (PP), Polystyrene (PS), Polyamide, ABS etc., can replace engineering plastics through reinforcement modifications. Furthermore, some engineering plastics achieve strengths comparable to metals through reinforcement, thereby expanding the depth and breadth of thermal plastics as structural materials in engineering applications. So, what are the four major advantages and disadvantages of modified plastic reinforcement? Let's discuss in detail.

Advantages of Reinforced Plastic Modification

-

Fiber Morphology: The greater the fiber aspect ratio (length/diameter), the higher the mechanical strength of the composite material. To maintain a high aspect ratio in composite materials, it is necessary to select fibers with a high aspect ratio and pay attention to preserving it during processing. However, during the extrusion and granulation process, fiber breakage frequently occurs, resulting in short glass fiber-reinforced plastics. Additionally, excessively high aspect ratios can cause production difficulties.

-

Excellent Fatigue Resistance: The strength and rigidity of reinforced plastics increase with an increase in fiber content, while the elongation decreases. Consequently, the materials exhibit improved resistance to creep. Fatigue failure refers to low-stress failure caused by the formation and propagation of microscopic cracks under alternating dynamic loads. Metal materials exhibit sudden failure from inside to outside without warning signs. On the other hand, fatigue failure in glass fiber-reinforced plastics gradually starts from weak points and progresses, showing clear signs before failure.

-

Good Thermal Performance: Unreinforced thermoplastic materials have poor heat resistance, with low heat distortion temperatures, limiting them to applications below 100℃. However, reinforcement modification significantly increases the heat distortion temperature of plastics, allowing products to operate in the range of 100-150℃ for extended periods. For example, the heat distortion temperature of unreinforced PA6 is about 60-80℃, while reinforced PA6 can reach 180-220℃. Some enhanced plastics can even surpass 300℃ in heat resistance. Some general plastics, after fiber reinforcement, can achieve heat resistance comparable to that of engineering plastics, while others can approach the heat resistance of specialized engineering plastics. Therefore, fiber reinforcement modification is an effective way to improve the heat resistance of plastics. Furthermore, while improving high/low-temperature resistance, it also reduces the material's thermal conductivity and coefficient of linear expansion, thereby reducing product shrinkage during molding and improving dimensional precision. Some fillers not only enhance product strength but also confer specific functions, such as improving electrical performance, flame retardancy, etc.

-

High Specific Strength: Specific strength is the ratio of material strength to density. Fiber-reinforced plastic materials can even exceed the specific strength of metals. The specific strength of reinforced plastics has already surpassed that of advanced alloy steel. Fiber-reinforced plastics are a type of lightweight, high-strength engineering structural material widely used in aircraft, automobiles, and other lightweight products to reduce fuel consumption, save energy, and facilitate maintenance through easy disassembly and replacement, thereby greatly reducing maintenance costs.

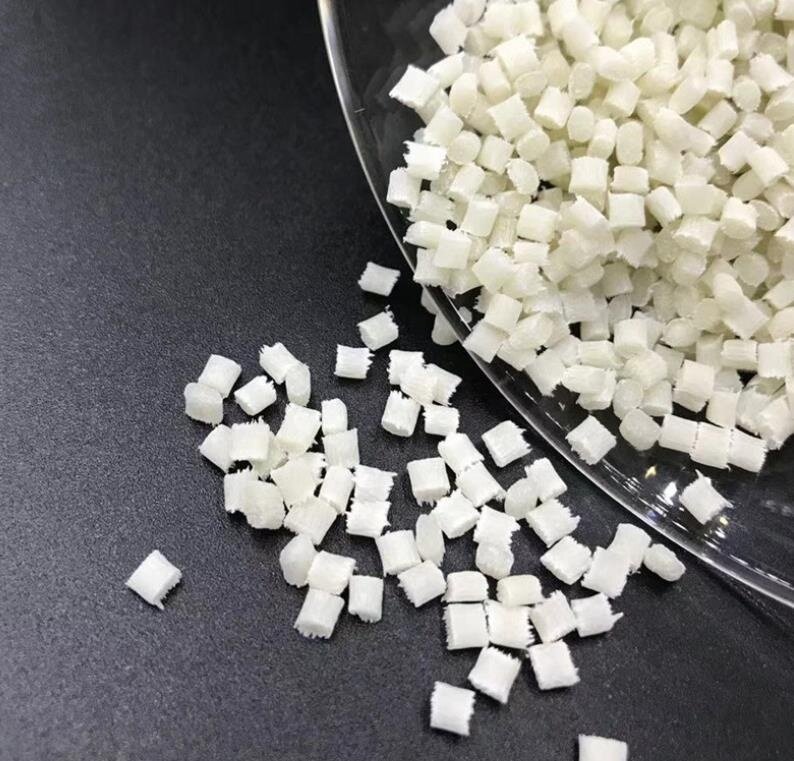

(Glass filled material)

Disadvantages of Reinforced Plastic Modification

-

High Hardness and Wear: Inorganic fillers used for reinforcement have high hardness and strength, resulting in relatively high wear on processing machinery and molds.

-

Reduced Flowability: Inorganic fillers generally have poor flowability, causing a decrease in melt flow index after plastic reinforcement and reduction in molding processability.

-

Surface Roughness: Most inorganic fillers worsen the surface roughness of products, leading to the occurrence of fiber protrusion issues.

-

Decreased Elongation and Impact Strength: Reinforced plastics often show reduced elongation and impact strength.

Conclusion:

Plastic reinforcement modification technology is continuously improving and advancing, with an increasing range of reinforcement materials being used. Glass fiber-reinforced plastics have gained widespread popularity due to their lightweight nature, high specific strength, good heat resistance, electrical insulation properties, excellent vibration damping and fatigue resistance, unique corrosion resistance, and easy-to-use molding processes. Additionally, with the advancement of cutting-edge technologies in aerospace and other fields, the development of reinforced materials with high strength, high modulus, and high-temperature resistance, such as carbon fiber, boron fiber, whiskers, etc., is also progressing rapidly.