Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

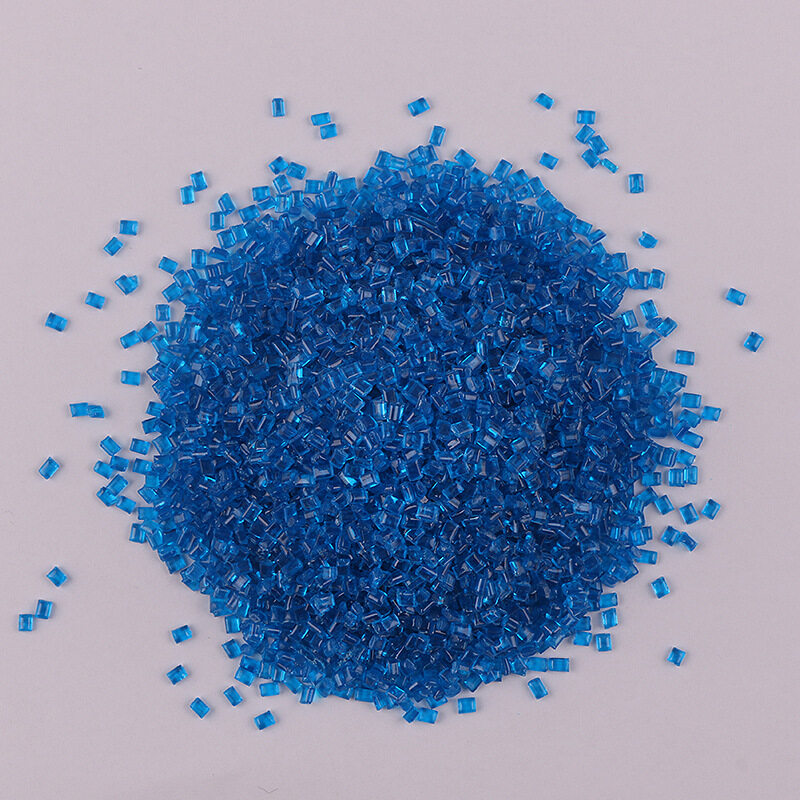

The Versatility and Applications of Polycarbonate Granules

Polycarbonate granules are a form of thermoplastic that are widely recognized for their exceptional strength, durability, and clarity. These granules are the raw material used in the production of various polycarbonate products, ranging from bulletproof glass to compact discs. In this blog post, we will delve into the properties of polycarbonate granules, their manufacturing process, and the myriad of applications they serve in today’s industrial and consumer markets.

Manufacturing Process of Polycarbonate Granules

Polycarbonate granules are manufactured through a process known as polymerization, where bisphenol A and phosgene react in a controlled environment to form polycarbonate resin. The resin is then cooled and cut into small, uniform granules that are easy to transport and handle. These granules are the building blocks for a multitude of polycarbonate products and can be easily melted and molded into desired shapes and sizes.

Impact Resistance and Security Applications

One of the most notable properties of polycarbonate granules is their high impact resistance. This characteristic makes them an ideal material for products that require durability and protection against breakage. For instance, polycarbonate granules are used to create the bulletproof glass used in security applications, such as bank teller windows and armored vehicles. The granules’ ability to absorb and disperse energy without shattering is crucial in these high-risk environments.

Optical Clarity and Applications

Another significant advantage of polycarbonate granules is their transparency. The clarity of polycarbonate is comparable to that of glass, yet it is much lighter and more shatter-resistant. This makes polycarbonate granules a popular choice for manufacturing lenses for eyewear, automotive headlamps, and transparent roofing materials. The material’s inherent UV resistance also adds to its suitability for outdoor applications, as it does not yellow or degrade under sunlight.

Thermal Resistance and Electronic Uses

Polycarbonate granules also exhibit excellent thermal resistance, which allows them to withstand extreme temperatures without losing their structural integrity. This property is particularly beneficial in the production of electronic components and appliances that may be exposed to high heat during operation. The thermal stability of polycarbonate granules ensures that products remain safe and functional even under challenging conditions.

Consumer Goods and Safety

In the realm of consumer goods, polycarbonate granules are used to make a wide array of items, including water bottles, sports equipment, and children’s toys. The material’s safety, as it is BPA-free and non-toxic, combined with its strength, makes it an excellent choice for products that are frequently used and require a high degree of resilience.

Medical Applications and Sterilization

The versatility of polycarbonate granules extends to the medical field as well. Medical devices and equipment, such as surgical instruments and drug delivery systems, often utilize polycarbonate due to its sterilizability and biocompatibility. The ability to repeatedly sterilize these products without degradation is essential in maintaining the stringent hygiene standards of medical environments.

Conclusion

In conclusion, polycarbonate granules are a vital material in modern manufacturing, offering a unique combination of strength, clarity, and thermal resistance. Their wide range of applications demonstrates their adaptability and the critical role they play in the development of innovative and reliable products. Whether it’s in the form of bulletproof glass, electronic components, or medical devices, polycarbonate granules continue to shape the world around us with their remarkable properties. As industries evolve and new challenges arise, the demand for polycarbonate granules is likely to grow, further cementing their status as a cornerstone of material science and engineering.