Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

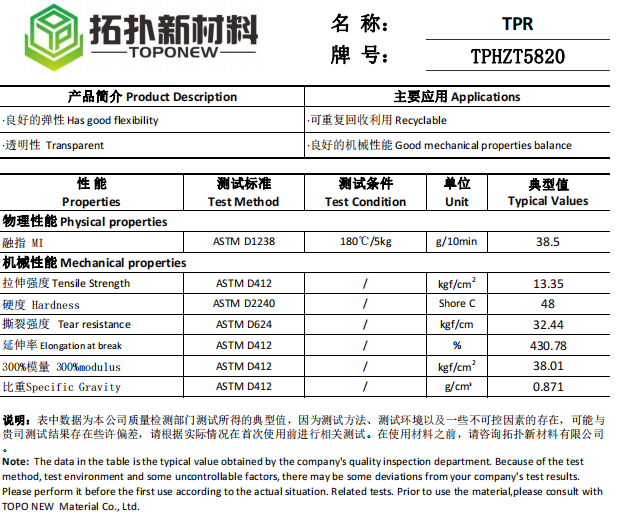

TPR TPHZT5820

Shore C 48,

Halogen Free

(Custom materials available according to your Technical Data Sheet)-产品简介

- Информация о продукте

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

Technical Data Sheet of TPR TPHZT5820 Plastic Raw Material TPR Granules

Suzhou Topo New Material – Premium TPR Plastic Pellets for Versatile Applications

At Suzhou Topo New Material, we pride ourselves on delivering high-performance TPR (Thermoplastic Rubber) plastic pellets that provide unmatched flexibility, durability, and ease of processing. As a leading manufacturer of modified plastic materials, we are committed to developing solutions that meet the needs of various industries, from consumer goods to automotive and industrial applications.

Why Choose TPR Plastic Pellets?

Exceptional Flexibility & Soft-Touch Feel: TPR pellets offer the elasticity of rubber combined with the processing ease of plastics, making them ideal for products requiring both flexibility and comfort.

Durable & Weather Resistant: Our TPR materials are designed to withstand challenging environments, providing long-lasting durability in products exposed to extreme temperatures, moisture, and UV radiation.

Easy to Process: TPR pellets can be easily molded, extruded, or injected into various forms, offering manufacturers greater efficiency and versatility in production.

Recyclable & Eco-Friendly: TPR is fully recyclable, making it a sustainable choice for companies looking to reduce environmental impact while maintaining product quality.

Applications of TPR Plastic Pellets:

Footwear: Ideal for shoe soles and other soft-touch components.

Toys & Consumer Goods: Safe, flexible, and durable for products requiring soft-touch features.

Automotive Parts: Used in interior components such as seals, gaskets, and handles, where flexibility and strength are key.

Industrial Uses: Suited for grips, seals, and soft-touch tools in various industries.

The Future of TPR Materials:

With growing demand for versatile, eco-friendly, and high-performance materials, the market for TPR plastic pellets is rapidly expanding. As industries continue to seek sustainable alternatives to traditional rubber and plastic, TPR’s unique blend of flexibility, durability, and recyclability positions it as a key material for future innovations.

Download

-

拓扑新材料 TPR TPHZT5820.pdf

Download 拓扑新材料 TPR TPHZT5820.pdf