Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

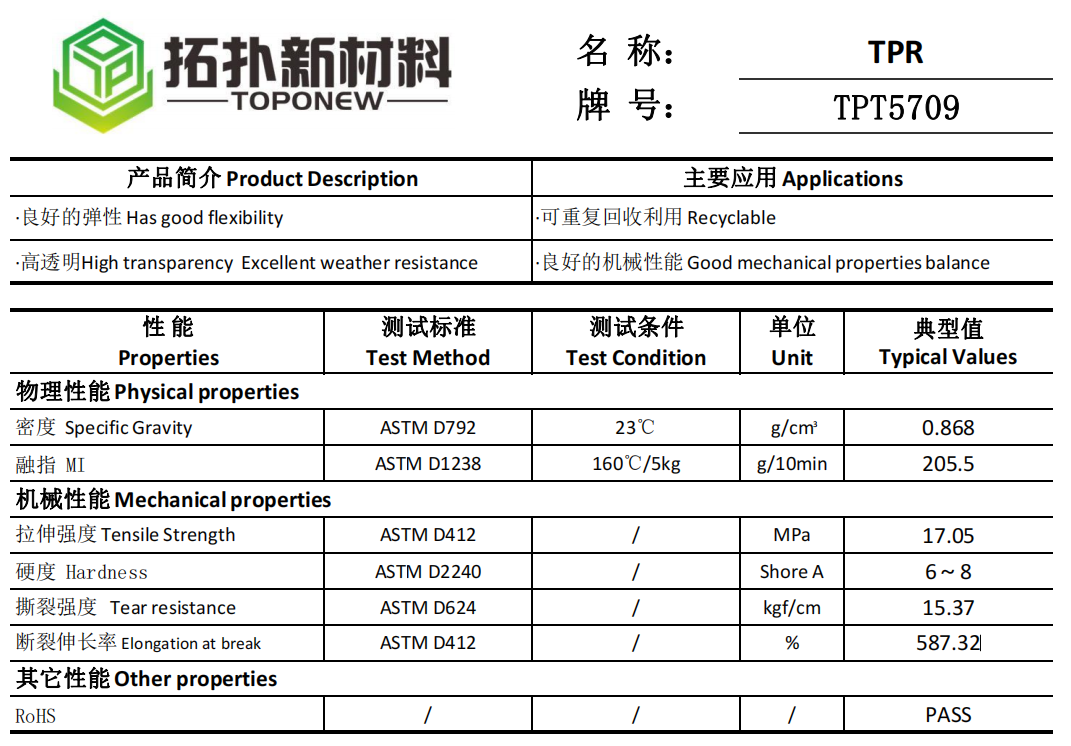

TPR TPT5709

RoHS PASS,

Shore A 6~8,

Money Band

(Custom materials available according to your Technical Data Sheet)

- Информация о продукте

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

Technical Data Sheet of TPR TPT5709 Plastic Raw Material TPR Granules

TPR (Thermoplastic Rubber) is a unique material known for its exceptional properties and versatile applications. As a leading TPR manufacturer, we offer top-quality TPR granules and TPR resins that are highly durable, flexible, and resistant to wear and tear. The elasticity of TPR makes it an ideal choice for various applications, with one popular example being the production of money bands. These bands benefit from TPR's ability to stretch and retain its shape, providing a secure and long-lasting solution for bundling money and other items. Explore the innovative uses of TPR materials with our premium TPR granules and resins for your next project.

Thermoplastic rubber (TPR) is a versatile material that combines the characteristics of rubber with the processing advantages of thermoplastics. Featuring a unique blend of flexibility and moldability, TPR is the ideal choice for a wide range of applications. This material is created using block copolymers such as SBS (Styrene-Butadiene-Styrene). Compared to traditional TPEs, which are predominantly made from SEBS (Styrene-Ethylene-Butadiene-Styrene) based polymers, TPR offers distinct advantages in various manufacturing processes thanks to its specific composition and properties.

TPR stands for Thermoplastic Rubber, which is a type of material that combines the properties of rubber and plastic. TPR compounds are a blend of thermoplastic materials, typically a plastic like polypropylene or polyethylene, with rubber particles or additives such as styrene-butadiene-styrene (SBS). This combination results in a material that exhibits both the flexibility and elasticity of rubber as well as the processability and recyclability of thermoplastics.

Here are some key characteristics and properties of TPR compounds:

-

Flexibility and Elasticity: TPR compounds are known for their flexibility and elasticity, making them versatile for applications that require deformation without permanent damage.

-

Soft Touch and Grip: TPR compounds often have a soft touch feel and provide good grip, which makes them suitable for applications in handles, grips, and overmolding.

-

Ease of Processing: TPR compounds can be injection molded, extruded, or blow molded due to their thermoplastic nature. They can be melted and reshaped multiple times without undergoing chemical degradation.

-

Chemical Resistance: TPR compounds can offer good resistance to chemicals, oils, and greases depending on the specific formulation.

-

Weather Resistance: Some TPR compounds can exhibit good weather resistance, making them suitable for outdoor applications.

-

Recyclability: TPR compounds are recyclable and can be reprocessed, reducing waste and environmental impact.

TPR compounds find wide applications in industries such as consumer goods, footwear, automotive parts, seals and gaskets, grips and handles, toys, and medical devices due to their unique combination of properties.

Download

-

TPR TPT5709.pdf

Download TPR TPT5709.pdf